SPECIFICATIONS

Brand Name: Feetech

Origin: Mainland China

Material: Plastic

Plastic Type: PC

RC Parts & Accs: Batteries - LiPo

Size: 10*10*10

For Vehicle Type: Cars

Use: Vehicles & Remote Control Toys

Upgrade Parts/Accessories: Lithium Battery

Remote Control Peripherals/Devices: Remote Controller

Tool Supplies: Battery

Quantity: 1 pcs

Technical parameters: KV1100

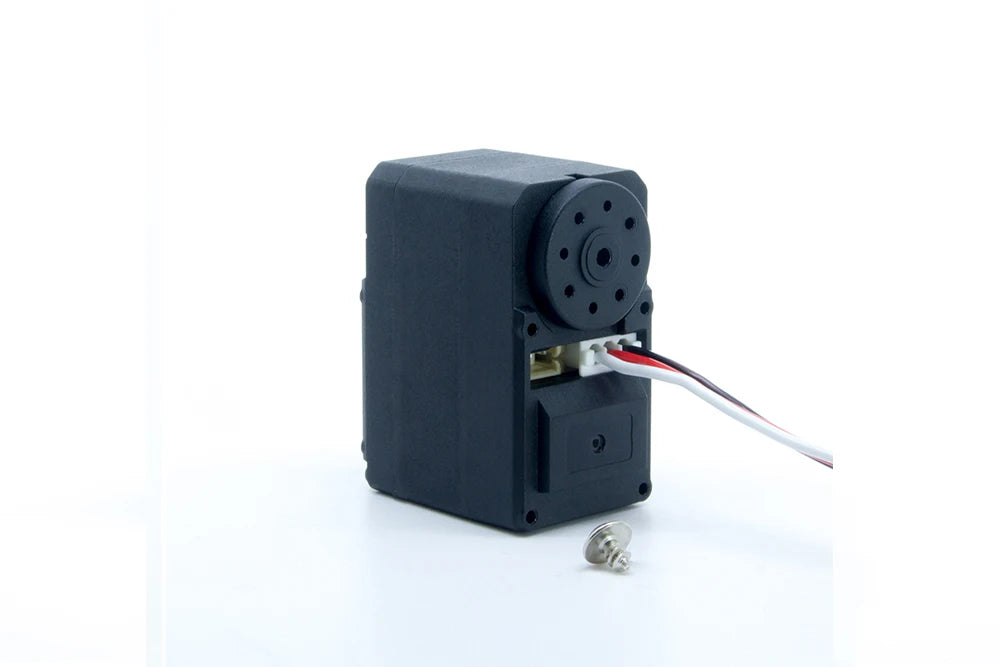

Model Number: SCS225-C006

Four-wheel Drive Attributes: Motors

Wheelbase: Screws

Model Number: SCS225-C006

Size: 45.23mm X 24.73mm X 35mm

Weight: 55± 1g

Gear type: Copper

Limit angle: NO limit

Bearing: Ball bearings

Horn gear spline: 25T

Motor: Coreless motor

Operating Voltage Range: 6-7.4V

Peak stall torque: 19.5kg.cm@6V

Rated torque: 6.5kg.cm@6V

Protocol Type: Half Duplex Asynchronous Serial Communication

|

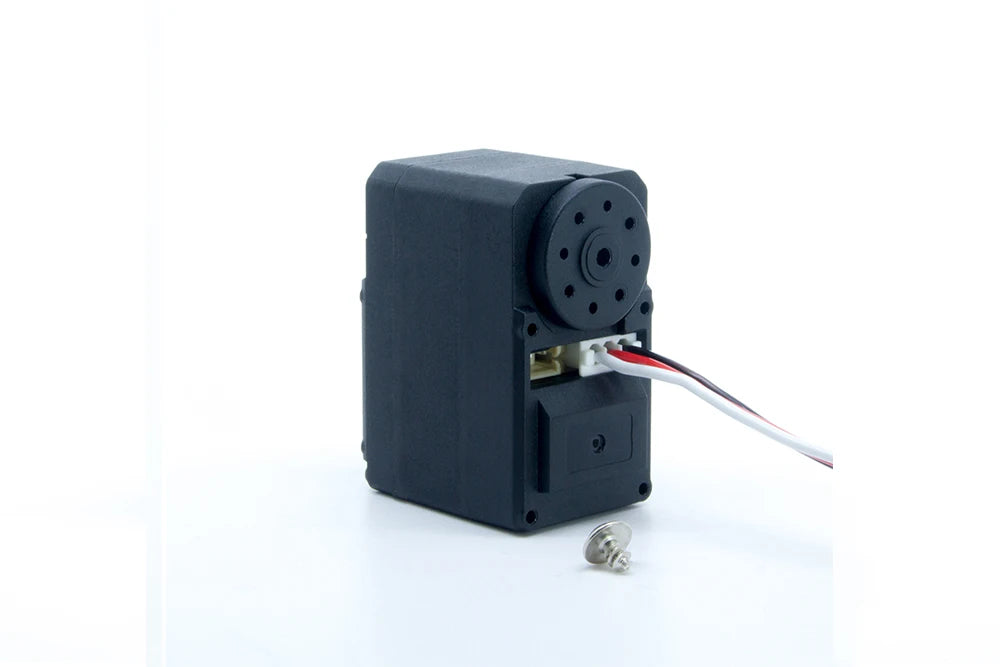

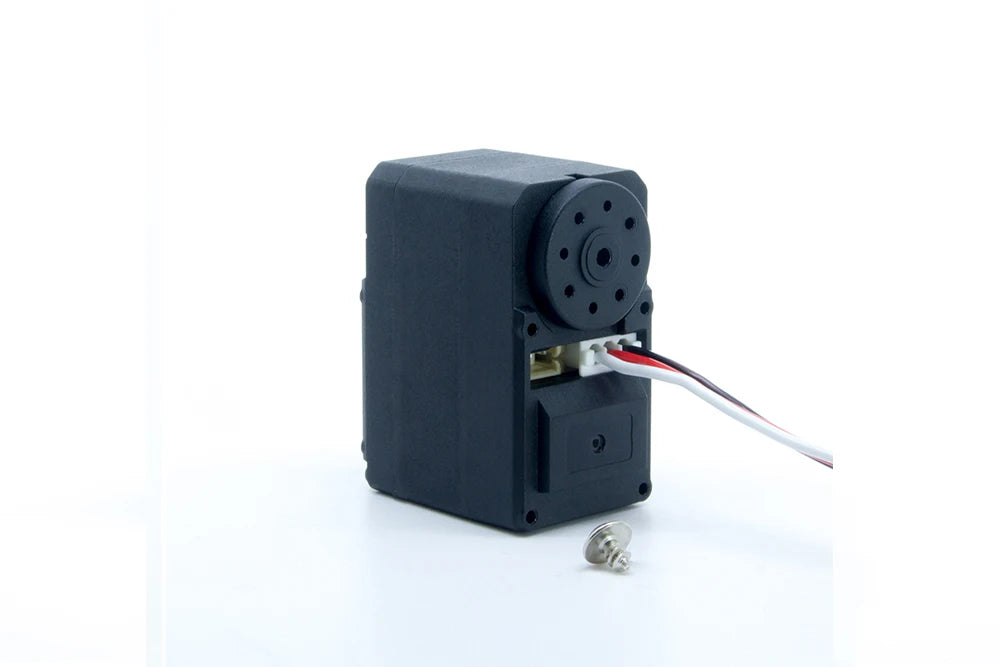

SCS225-C006 is 7.4V 19kg serial bus servo .adopt plastic case .metal gearbox、core motor. Feetech self researched and developed TTL control board. high quality potentiometer. 25T output shaft. The stall torque is 19kg.cm. effective control angle is 300 °. with servo mode and continuous motor working mode. feedback position. speed. voltage. temperature. current. load parameters. so as to achieve overload protection. It is suitable for teaching. maker. robot joints and other small torque transmission applications.

|

|

Model:

|

SCS225-C006

|

|

Product Name:

|

7. 4V 19kg. cm Serial Control BUS Servo

|

|

Storage Temperature Range

|

-30℃~80℃

|

|

Operating Temperature Range:

|

-20℃~60℃

|

|

Size:

|

A:45.23mm B:24.73mm C:35mm

|

|

Weight:

|

55± 1g

|

|

Gear type:

|

Copper

|

|

Limit angle:

|

NO limit

|

|

Bearing:

|

Ball bearings

|

|

Horn gear spline:

|

25T

|

|

Case:

|

PA+GF

|

|

Connector wire:

|

15CM

|

|

Motor:

|

Core Motor

|

|

Operating Voltage Range:

|

4-7.4V

|

|

No load speed:

|

0.192sec/60°@7.4V

|

|

Runnig current(at no load) :

|

150mA@7.4V

|

|

Peak stall torque:

|

19kg.cm@7.4V

|

|

Rated torque:

|

6.3kg.cm@7.4V

|

|

Stall current:

|

2.5A@7.4V

|

|

Command signal:

|

Digital Packet

|

|

Protocol Type:

|

Half Duplex Asynchronous Serial Communication

|

|

ID range:

|

0-253

|

|

Communication Speed:

|

38400bps ~ 1 Mbps

|

|

Control Algorithm

|

PID

|

|

Neutral Position

|

180°(511)

|

|

Running degree:

|

300°(when 0~1024)

|

|

Feedback:

|

Load. Position. Speed. Input Voltage. Current .Temperature

|

|

Resolution deg/pulse

|

0.322°(330°/1024)

|

|

Our products have passed CE and ROHS certification.and most of them have applied for appearance patents and utility model patents

Our products have achieved compliance with CE. RoHS. and REACH regulations and hold patents for their design and appearance.

OUR SERVICES: We specialize in Original Design Manufacturing (ODM) and Original Equipment Manufacturer (OEM) solutions. as well as custom-made products. Our comprehensive services include electronic design. structural design. and one-stop production for customized solutions.

Specialized in ODM and OEM and Custom Made 1.Your Logo lable or print

2.Servo Wire

3.Packing:PE Bag.Colur Box.plastic box wity

your Logo

4.Cable connector

5.Customized Various of wide working voltage servo

Product Usage

Application: Our servo motor is suitable for various applications such as robotic grippers. arms for robotic systems. RC helicopters. aircraft models. cars. ships. and other precision control mechanisms. With its high 20kg torque and intelligent design. this servo can be used in DIY projects or as part of automation equipment.

Electronic control Function:

Electronic control Function:

1.Acceleration start stop function: speed and acceleration value can be set. motion effect is more gentle.

2.High precision. 360 degree absolute position 4096 bit precision. the highest position resolution is 0.088 degrees. if the control is 90 degrees. input 4096 / 360 * 90 = 1024. if the control is 180 degrees. input 4096 / 360 * 180 = 2048. so as to calculate.

3.There are four working mode switching (mode 0 position servo. mode 1 speed closed-loop. mode 2 speed open-loop. mode 3 step servo).

1)、Mode 0:Location mode. the default mode. In this mode. 360 degree absolute angle control can be realized. Support acceleration movement.

2)、Mode 1:Speed closed-loop. in the programming interface. the operation mode is set to 1. switch to speed closed-loop mode. and enter the corresponding speed in the speed column to run.

3)、Mode 2:Speed open-loop. in the programming interface. the operation mode is set to 2. switch to speed open-loop mode. and enter the corresponding time in the time column to run.

4)、Mode3:Step mode: in the programming interface. the maximum / minimum angle limit is set to 0. and the operation mode is set to 3. Switch to step mode. Enter the position in the position bar to step towards the target position. Click the position again to continue to step in the same direction.

4、Multi turn mode. 360 degree absolute control and feedback. under the highest accuracy. the absolute position control can be plus or minus 7 turns. but the number of power cycles is not saved. only the absolute position feedback value is retained.

5、One key calibration. 360 degree angle installation at any position. (40 (decimal) address input 128 (decimal)) one key correction current position is the middle (2048 (decimal)).

6、TTL communication level. half duplex asynchronous communication. bus protocol support to adjust read and write parameters. and add synchronous read function (send an instruction to receive the read back instruction from each servo on the bus in turn.)

7、Multiple protections. (overload. overcurrent. overvoltage. overheating. switch setting. condition parameter changing)

1)、Overload protection: through position detection. during the movement from the starting position to the target position. when the current position is detected to be not the target position after encountering the blocking of obstacles. the unloading force lasts for 2S (20% of the default blocking force). Until a new command is triggered. Release protection

2)、Overcurrent protection: through the set current value. check whether the current reaches the set current value. When it reaches the set current value. release the force (the default torque is 0). Until a new command is triggered. Release protection

3)、Over voltage protection: detect the current voltage value. If it exceeds the set voltage value. the alarm will display over-voltage.

4)、Overheat protection: detect the current motor temperature. If the temperature exceeds the set value. the alarm will display overheat.

8:Multiple feedback:

1)Load feedback: the current control output drives the voltage duty cycle of the motor. and the full scale is 1000 = 100% torque output.

2)Current feedback: The servo working current. 1 = 6.5mA

3)Voltage feedback: The servo working voltage.70=7V .0.1V

4)Temperature feedback: internal working temperature of current servo(measuring temperature)。

5)Speed feedback: feedback the speed of current motor rotation. and the number of steps in unit time (per second)

9、Open PID parameters.

FEETECH 7.4V 20KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo

Details Images

FEETECH 7.4V 20KG.CM Plastic Case Metal Gear Magnetic Encoder Double shaft TTL Serial Bus Servo

Electronic control Function:

1.Acceleration start stop function: speed and acceleration value can be set. motion effect is more gentle.

2.High precision. 360 degree absolute position 4096 bit precision. the highest position resolution is 0.088 degrees. if the control is 90 degrees. input 4096 / 360 * 90 = 1024. if the control is 180 degrees. input 4096 / 360 * 180 = 2048. so as to calculate.

3.There are four working mode switching (mode 0 position servo. mode 1 speed closed-loop. mode 2 speed open-loop. mode 3 step servo).

1)、Mode 0:Location mode. the default mode. In this mode. 360 degree absolute angle control can be realized. Support acceleration movement.

2)、Mode 1:Speed closed-loop. in the programming interface. the operation mode is set to 1. switch to speed closed-loop mode. and enter the corresponding speed in the speed column to run.

3)、Mode 2:Speed open-loop. in the programming interface. the operation mode is set to 2. switch to speed open-loop mode. and enter the corresponding time in the time column to run.

4)、Mode3:Step mode: in the programming interface. the maximum / minimum angle limit is set to 0. and the operation mode is set to 3. Switch to step mode. Enter the position in the position bar to step towards the target position. Click the position again to continue to step in the same direction.

4、Multi turn mode. 360 degree absolute control and feedback. under the highest accuracy. the absolute position control can be plus or minus 7 turns. but the number of power cycles is not saved. only the absolute position feedback value is retained.

5、One key calibration. 360 degree angle installation at any position. (40 (decimal) address input 128 (decimal)) one key correction current position is the middle (2048 (decimal)).

6、TTL communication level. half duplex asynchronous communication. bus protocol support to adjust read and write parameters. and add synchronous read function (send an instruction to receive the read back instruction from each servo on the bus in turn.)

7、Multiple protections. (overload. overcurrent. overvoltage. overheating. switch setting. condition parameter changing)

1)、Overload protection: through position detection. during the movement from the starting position to the target position. when the current position is detected to be not the target position after encountering the blocking of obstacles. the unloading force lasts for 2S (20% of the default blocking force). Until a new command is triggered. Release protection

2)、Overcurrent protection: through the set current value. check whether the current reaches the set current value. When it reaches the set current value. release the force (the default torque is 0). Until a new command is triggered. Release protection

3)、Over voltage protection: detect the current voltage value. If it exceeds the set voltage value. the alarm will display over-voltage.

4)、Overheat protection: detect the current motor temperature. If the temperature exceeds the set value. the alarm will display overheat.

8:Multiple feedback:

1)Load feedback: the current control output drives the voltage duty cycle of the motor. and the full scale is 1000 = 100% torque output.

2)Current feedback: The servo working current. 1 = 6.5mA

3)Voltage feedback: The servo working voltage.70=7V .0.1V

4)Temperature feedback: internal working temperature of current servo(measuring temperature)。

5)Speed feedback: feedback the speed of current motor rotation. and the number of steps in unit time (per second)

9、Open PID parameters.